The Basic Principles Of Motorcycle Parts New Zealand Specialists

Table of ContentsExcitement About Motorcycle Parts New Zealand SpecialistsIndicators on Motorcycle Parts New Zealand Specialists You Should KnowWhat Does Motorcycle Parts New Zealand Specialists Mean?Facts About Motorcycle Parts New Zealand Specialists UncoveredThe Single Strategy To Use For Motorcycle Parts New Zealand SpecialistsMotorcycle Parts New Zealand Specialists for BeginnersThe Only Guide for Motorcycle Parts New Zealand SpecialistsHow Motorcycle Parts New Zealand Specialists can Save You Time, Stress, and Money.

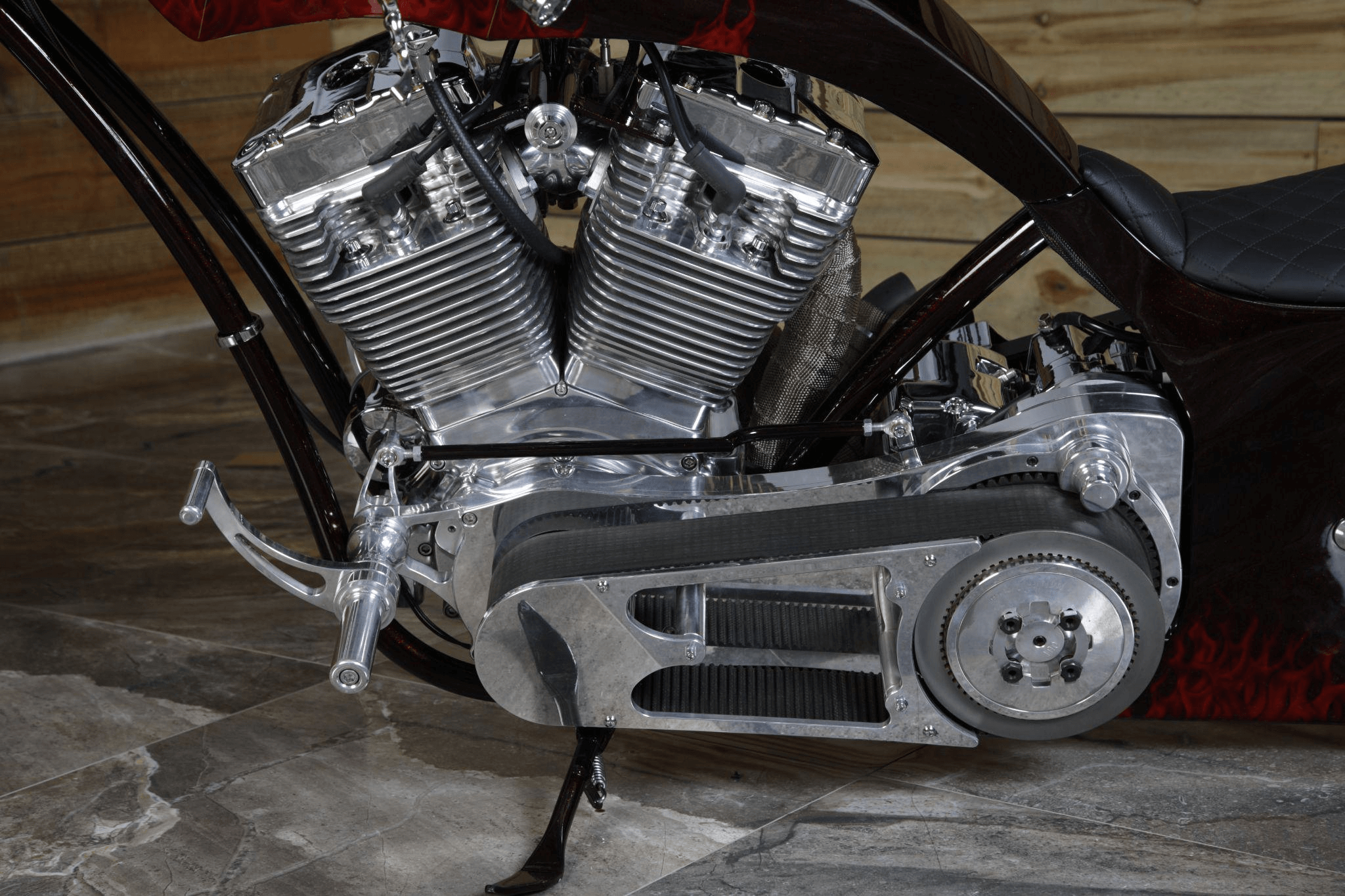

So, connect to one of our experts today.CNC machining technology is promptly coming to be the centerpiece of various production procedures around the globe as a straight result of its lots of benefits over various other methods. Furthermore, the industries that make motorcycles have actually gotten on board with this fad. The most innovative companies are currently establishing their engine components and wheels using machining techniques originally developed for motorbike components.

You might be asking yourself why we utilize. Now that we have your attention allow us clarify the rationale behind this modern-day development in the motorcycle manufacturing industry.

What Does Motorcycle Parts New Zealand Specialists Mean?

On top of that, you have total control over the look of the elements, also to the minute information. Periodically, motorcyclists might decide to spruce up their trip by installing aftermarket elements or customizing the bike's makeover. Once more, computer mathematical control (CNC) machining is the most useful method. Upgrades might be of any type of form and design you want.

Rumored Buzz on Motorcycle Parts New Zealand Specialists

CNC machining may be used to make practically all of a motorcycle's steel and plastic parts. To continue, we'll go over numerous machined components for motorcycles.

When personalizing the wheels, the disks are where the focus must be. The bulk of them are constructed of light weight aluminum. Light weight aluminum alloys are popular for the exceptional machining capabilities that they possess. Milling procedures are used to obtain the desired level of wheel customization. An additional aspect of the motorcycle that might be individualized is the tires.

Facts About Motorcycle Parts New Zealand Specialists Revealed

When it concerns a lorry (or a motorcycle), the most vital element is the engine. Several people suggest to it as the "heart" of the car. On the other hand, the camshaft, the cyndrical tube head, and the pistons have a tendency to be complex and require layouts with a high degree of precision.

Use only top quality products, however, because these lights are crucial for the security of motorcyclists and various other chauffeurs or people on the roadway, specifically at evening. Bike fronts lights have 3 primary parts: the bulb, or light source, the lens, and the housing.

Milling procedures with a flawless finish would result in the lenses having a reflective top quality that resembles that of a mirror. The cover, on the other hand, is not composed visit this site right here of fragile materials; rather, it is constructed out of tough polymers that can be machined into even more complex patterns.

Motorcycle Parts New Zealand Specialists - An Overview

Motorbike producers typically cast these parts, yet only for the manufacturing of bespoke parts. Machining on five axes in today's globe is the means by which any type of style form may be realized.

The success of the procedure is contingent on the mill cutters' capacity to compute subtle and complicated angles precisely. Choose Runsom for your tailored motorcycle parts! We have the capacity to make difficult and elegant components making your motorbike unparalleled. Most are crafted from light weight aluminum or steel alloys, each of which has its usages and benefits.

Right here are a couple of examples of steels usually used in motorbike part machining. Aluminum is the main product used by business specializing in creating personalized motorcycle components to develop the majority of these components. In the past, we would certainly construct our engines out of cast iron. On the various other hand, aluminum is promptly becoming the product of choice, partly because of the truth that it is top article a lot more lightweight.

Zinc describes an additional metal that is extremely light in weight and has great machining qualities as a result of its high mechanical strength. This product might be developed into practically any form and keeps its measurements well. Also mission-critical elements that require a high degree of accuracy might take advantage of their use.

5 Easy Facts About Motorcycle Parts New Zealand Specialists Explained

An additional metal that sees hefty usage in the production of CNC-customized parts is magnesium. It is among the lightest steels that are currently easily accessible and has outstanding machinability attributes and strength appropriate with its reduced weight. One of the disadvantages of magnesium is that its dust may quickly ignite.

Their most typical usage in producing various motorcycle elements is bolts, such as screws and screws. Their low sensitivity to oxidation and deterioration makes them ideal for this use.

The Buzz on Motorcycle Parts New Zealand Specialists

It appears that CNC transforming and grating are the foundational procedures. Alternate techniques exist, such as exploration. Let's examine many of these machining strategies detailed. The CNC transforming method is considered a subtractive production approach. On top of that, it requires keeping bars of product, frequently plastic or steel, ready and then turning a cutting device to eliminate areas of the material as the product is transformed.

These approaches are equally vital and produce elements with high precision and constant top quality. They are respectively: grinding, laser cutting, and drilling. The term "surface finish" describes post-processes after the first machining phase. Motorcycle Parts New Zealand Specialists. The procedures help improve the general top quality of the machined bike components. Below are the brief introduction, advantages and disadvantages of 5 surface area therapy approaches.

6 Easy Facts About Motorcycle Parts New Zealand Specialists Shown

Comments on “The 8-Second Trick For Motorcycle Parts New Zealand Specialists”